Mennie Machine Company

A Vision for Quality

Driving down Route 71, about two hours southwest of Chicago, you pass classically American countryside including farms, fields, small businesses, and homes. Then, suddenly, off in the distance, a very large, white structure, shimmering in the sun, begins to appear on the horizon. That’s the Mennie Machine Company, in Mark, Illinois (www.mennies.com). As you pull onto Mennie Drive and enter the grounds, what you see is a modern, state-of-the-art building, complete with Roman columns and statues. Inside is a 225,000 sq. ft. metal machining facility, employing over 300 people, with annual sales of more than $50 million.

However, owner Cheryl Mennie, tells us things were not always so. Cheryl and her husband Hubert started the company in their home and garage in 1969. It has now grown to proportions Cheryl said “neither of us would have imagined.” Following Hubert’s death in 2009, Cheryl has continued to run the company, and now her entire family is also working in the business. Over the years, Mennie Machine Company has survived the economic downturns that affected metal machine operations nationwide, in particular the well-documented drop in the manufacturing sector from 2008 – 2010. Today, business has soften again, and

Is expected to stay down thru 2013.

Recently, on tour of the facility with Mennie’s Quality Manager, Kyle Goetsch, we learned how the Mennie Machine has survived, and thrived. “The majority of our business is in fuel system hydraulic parts, earth moving components, auto industry, and heavy truck transmission parts, used in mission-critical transportation applications.” Goetsch said. “Part of our company’s quality policy states: ‘We will meet, or exceed, our contractual obligation for product quality,’ and we mean it. There is simply no room for error when working with such critical transportation parts,” Goetsch said.

Mennie Machine serves customers across the United States, and also ships to Mexico, Singapore, Japan, Poland, and Canada. Those customers include Saur-Danfoss, Eaton Hydraulics, Bosch Rexroth, Poclain Hydraulics, Allison Transmission, American Axle, Caterpillar, and Cummins. Mennie Machine is ISO TS 16949 Certified, and is implementing Statistical Process Control (SPC) shop-wide.

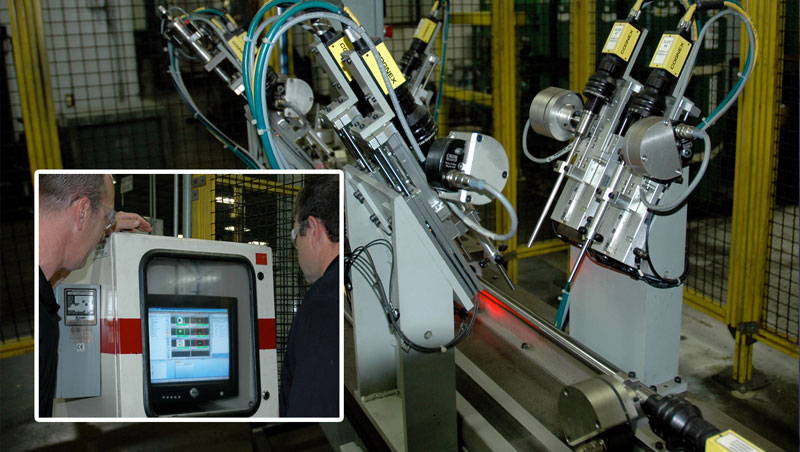

Visual inspection, in particular borescopic inspection, is a key component of Mennie Machine’s quality procedures. For some assignments, borescopic inspection is conducted in the traditional way, in conjunction with various methods of thermal and manual de-burring. After a part has been de-burred, it is inspected using a borescope, by eye, to assure the removal of all burrs and debris (see photo). However, industry-wide, borescopes are increasingly being connected to video cameras to allow on-screen viewing of live borescopic inspections, as well as the capture of video footage and still photographic images. Knowing this, Mennie Machine Company has taken borescopic visual inspection to a whole new level with its custom designed robotic inspection cell (see photos). It is a fully automated, robot load, robot unload, cell inspection.

Kyle Goetsch said, “Teaming-up with R.R. Floody, Inc. (www.rrfloody.com) we basically developed a database of known good and bad product. Using video cameras attached to 8 different Hawkeye Borescopes (www.gradientlens.com), inspection images can be captured inside virtually any machined part. Inside one fuel system part alone, Mennie captures, 24 different images using the Hawkeye Borescopes and Cognex cameras. Those images are then displayed, and stored, on a computer and monitor outside the manufacturing cell’s cage (see photo). Then, the images are compared in a database we’ve developed that distinguishes defect from non-defect, good from bad. It can even measure part characteristics such as chamfer radii, and other critical measurements.”

“Some of the components we are running through this cell are actually serialized so when that component runs through the system it does the inspection first, then, if it passes the inspection, it records the serial number” Goetsch said. “So, whether a part passes or fails, the vision system records the serial number of that field component. From there, if it passes, it goes through a verification stamp station, and then it is passed on to the outgoing robot. If the part fails, it goes into an isolation station within a cage. Our inspector then goes in manually and addresses the defect. With that serial number, we can go back and actually review the photo image that was captured by the borescope and find out exactly what the defect was. Whether it’s a burr, or another defect, we can go back and rework it. If it is a definite defect, then it’s put in with the non-conformed product.”

“In putting this robotics system together, and in visual inspection stations around the shop, we tested a number of different borescopes. Hawkeyes are clearly the best for our needs, with regard to magnification, craftsmanship and cost. Most important, we haven’t found anything that can match them for adequate lighting at the point of inspection” Goetsch said. “The last thing I would ever want to hear is that a defect went out to a customer that we could have found with proper visual inspection.”