Common Remote Visual Inspection Tools

April 30, 2021

Now more than ever, service industry businesses need methods to work safely and at a distance. One tool that solves both these issues is the humble camera. Through the use of a lens distanced from the immediate eyesight of the viewer, technicians and their supporting teams can study problems in detail. Moreover, team members don’t all have to be present thanks to the technology of live streaming video and screen feeds. Some of the more common remote visual inspection tools include mounted cameras, device cameras, and various borescopes.

Offsite Remote Inspection

Depending on the industry, common cameras can be effective. In particular, when a technician needs to cross-reference work with a team lead, the ability to capture and project a workspace remotely is very useful. Especially in a time where the number of people working nearby may be limited. The primary difference between using this type of camera is the lens perspective.

Webcams mounted on hardhats and even work tablet cameras are a useful quick solution, providing high enough resolution and connectivity. Most mounted cameras or those found on general use devices have a wider field of vision. The result is a useful holistic snapshot of a problem area rather than a close-up, more detailed look.

Onsite Remote Inspection

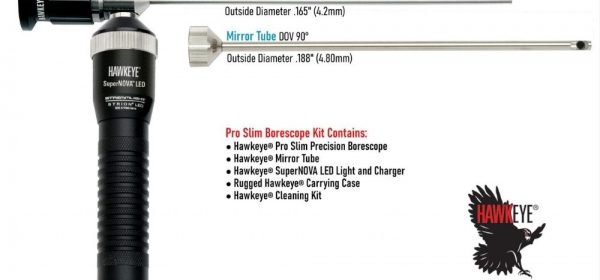

When the situation calls for inspection in close-up defined detail, the best common remote visual inspection tools have long been borescopes. The original design features a narrow metal tube with a camera mounted at the end. Primarily, this style is designed to be inserted into narrow passages with straight paths of entry, such as pipes. Gradient Lens carries a wide selection of rigid borescopes for sale, each with unique specs for investigating different size openings.

Besides rigid types, flexible varieties are also commonly used across many industries. Using fiber-optic technology, the camera is mounted on an array of cables. The difference is immediate, as these borescopes can explore a much wider range of irregularly shaped paths. As such, they’re highly applicable for investigating complex constructs, such as engine components and vent systems.

Finally, there are videoscope-type borescopes that sport more advanced imaging technology than both previous types. Videoscopes also use a flexible wire design but lack fiber optics, allowing for a more consistent high-definition image.